Cost-Effective Superior Quality Low Cost Container Dorm for Laborers

- Place of Origin: Shangdong, China (Mainland)

- Brand Name: QUALITY

- Model Number: Container house

- Material: Container

- Use: Camp, school, dormitory, mining

- Standard: ISO/CE/AS/US/CA

- Roofing: Customized

- Insulation: Fiberglass/ Rock wool / PU

- Features: Energy saving / Fast Assembly

- Using Life: 70 Years

- Design: Plan & 3D Model & Structral D

Cost-Effective Superior Quality Low Cost Container Dorm for Laborers

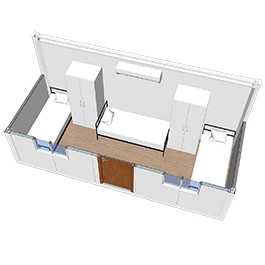

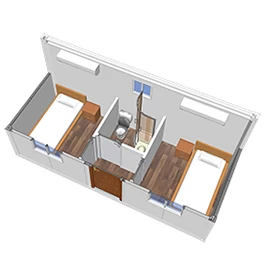

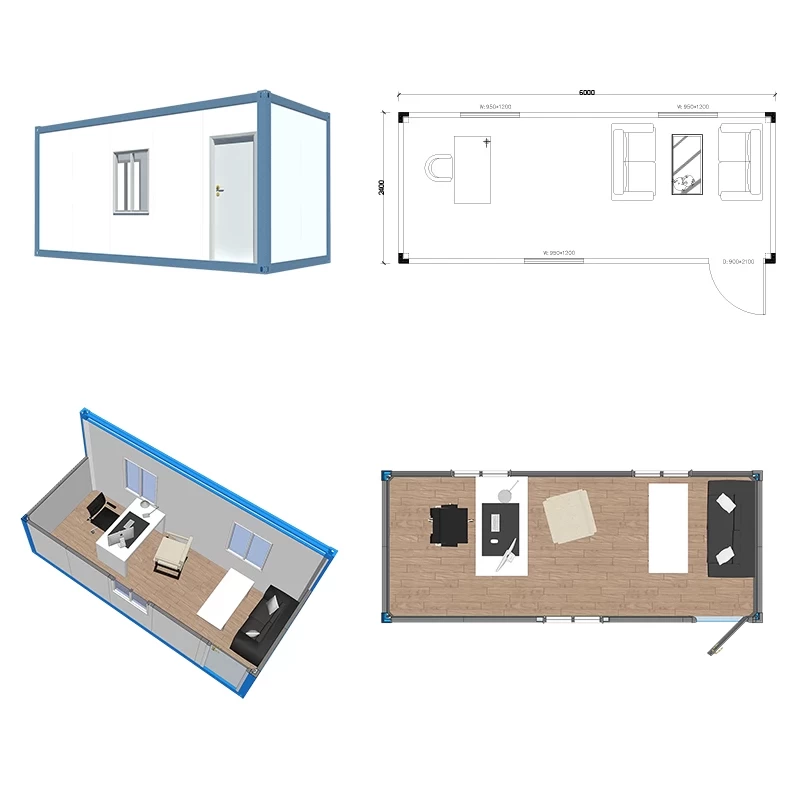

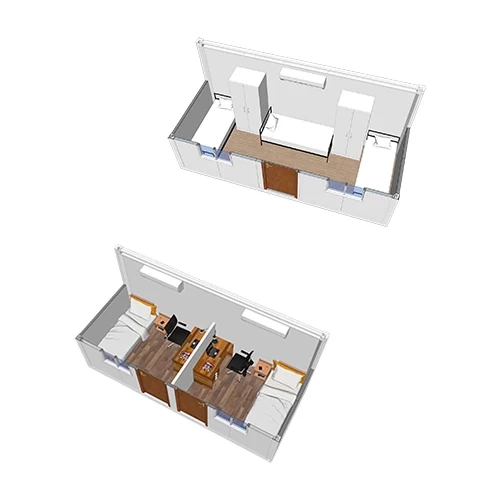

| Product Photo |

Prefab Container Dorms: Innovative, Efficient, and Future-Ready Housing Solutions

Prefabricated (prefab) container dorms are transforming the landscape of modern living by combining cutting-edge modular construction with sustainable design. These structures, built off-site using repurposed shipping containers, offer a fast, flexible, and eco-conscious alternative to traditional housing. Ideal for universities, corporate campuses, disaster relief, and urban developments, prefab container dorms deliver unmatched advantages:

1. Rapid Deployment & Time Efficiency

Prefab container dorms are manufactured in controlled factory environments, slashing on-site construction time by up to 70%. Modules arrive pre-insulated, wired, and fitted with plumbing, enabling quick assembly into functional living spaces—perfect for urgent housing needs or tight project deadlines.

2. Enhanced Sustainability

By upcycling steel shipping containers, these dorms reduce material waste and carbon emissions. Factories optimize energy use during production, while integrated green features like solar panels, rainwater harvesting systems, and energy-efficient HVAC further minimize environmental impact.

3. Customizable & Scalable Designs

Prefab modularity allows limitless customization. Units can be tailored for single or shared occupancy, with options for private bathrooms, kitchens, or communal areas. Need to expand? Simply add more containers horizontally or vertically, adapting to evolving space requirements without disruption.

4. Cost Savings

Streamlined manufacturing reduces labor and material costs. Bulk production of standardized modules cuts expenses, while reduced construction timelines lower financing and overhead fees. Prefab dorms also require less maintenance due to durable, corrosion-resistant materials.

5. High-Quality Living Standards

Modern engineering ensures comfort and safety. Factories incorporate advanced insulation, soundproofing, and fire-resistant materials, creating climate-controlled, quiet, and secure spaces. Smart technology integration (e.g., IoT sensors, app-controlled utilities) elevates convenience for tech-savvy residents.

6. Portability & Reusability

Prefab container dorms can be disassembled, relocated, or repurposed with minimal effort. This mobility makes them ideal for temporary projects (e.g., event housing, construction camps) or regions prone to shifting demographics or environmental risks.

Applications Across Sectors

Education: Solve student housing shortages with scalable, budget-friendly dormitories.

Corporate Housing: Provide comfortable, cost-effective lodging for remote workers or temporary staff.

Disaster Response: Deploy rapidly as emergency shelters with essential amenities.

Eco-Tourism: Create minimalist, low-impact cabins that blend with natural surroundings.

Prefab container dorms redefine affordable, sustainable living without compromising quality or aesthetics. By merging industrial innovation with human-centric design, they pave the way for a smarter, greener future in global housing.

Container Dorm for Laborers

| Product Detail |

| NORMAL QUALITY | ||

| NO | ITEM | DESCRIPTION |

| 1 | bottom frame | beam thickness 2.5mm |

| secondary purlin C120*60*1.7mm | ||

| 50mm glasswool insulation | ||

| 0.23mmcovering tile | ||

| 2 | top frame | beamthickness 2.5mm |

| Z molding part | ||

| secondary purlin 80*40*1.3mm | ||

| 50mm glasswool insulation+PE film | ||

| 0.5mm steel sheet | ||

| 3 | column | 2526*210*150*2.5mm |

| 4 | floor board | 18mm fiber cement board |

| 5 | floor covering | 1.6mm PVC vinyle flooring |

| 6 | steel door | T75 0.6mm,size 845*2035 |

| 7 | PVC window | pvc sliding window 1130*1100 double glasses,flying screen |

| 8 | wall panel | V1150,75mm glasswool sandwich panel0.4/0.450KG/m³ |

| 9 | Accessories | φ50mmPVC pipes |

| 831*0.4mm ceiling | ||

| 75 channel | ||

| PVC skirting | ||

| 0.4mmcolumn cladding | ||

| rivet,screw,glue,etc. | ||

| 10 | Electric | Industry plug,distribution box,4 socket,1switch,2 light |

| 11 | Lifetime | 10 years |

Tel:0086-13153691144

Contact Person:Sales Department

PDF Show:PDF

-Heya-Low-Price-Prefab-Villa-Prefabricated-Steel-Structure-Villa-Made-In-China.jpg.webp)